If you are interested in making clean crisp lines in a tattoo you need to first select the appropriate needle. Batel skater here and this is my part 2 of how to tattoo on this tutorial i am giving you the basics of how to set up a machine and tune.

How To Set Tune A Tattoo Machine Youtube

Arrow 3 points to the contact screw screw it downward towards the front spring to the appropriate gap width for shader or liner.

. Try to rush through the lining and outline of the design. If not pivot the contact screw up or down till it is level. When you are done tighten the thumbscrew again to lock the contact screw in place and let go of the armature bar.

Hold your tattoo machine so the coils are at eye level. Remove the retaining bar on the contact screw on the top back of the tattoo machine. On Sunday 18 of November 2012 I was giving a seminar on coil tattoo machine assembling and tuning at Evolution tattoo shop in Oxford it was a real great day we were a small group of professional tattoo artists everyone got the chance to pick up his tattoo machine frame and choose some coils and parts and choose the springs and.

After youve set the desired gap always ensure to tighten the contact screws locking device. Push to finish the line past the point of tolerance the person getting the tattoo has. A liner must run between 110 and 130 hertz.

How to tune a tattoo machine tuning a tattoo machine how to tune a tattoo machine step by step 18 subtitles availableif this video helped you please bu. Use a needle that has not been kept in a sealed package. This is because when lining your lines are delicate and small.

Setting up a tattoo machine is probably easier than you might think. Press down on the armature bar and see if the front coil. Tattoo artists deal with their tattoo machine everyday and much understand well how to tune it since tattoo machines are absolutely accurate devices that creates body art work.

Proper gap between the armature bar. Step 5 Check the needle while the tattoo gun is activated. When you identify the gap between the front spring and contact screw you should loosen the tattoo machines thumb screw to adjust the contact screw.

If youre switching from shader to liner or vice versa screw the contact screw to the desired width prior to tightening up the thumbscrew. Doing lining work is one of the most. The width of your contact screw and front spring should be thicker than a dime or the width of a dime.

Next check to see if your spring coil is properly attached in the grooves of each side of the needle barif its not then you might need to be re-tensioning them after theyve been loosened up by screwing them together too much. If the power supply is weak or too low there will not be enough current to move the armature bar. The nickel and dime method of tuning tattoo machines.

To be extra particular remove the clip cord from the clip. Tattoo machine Building Tuning seminar. Teaching you ow totune a tattoo machine since no oneon youtube doesAll these videos but no definite answers so i posted thisI would like feedback from.

Before continuing with your work check the functionality of your tattoo machines new setup. The best way to check the alignment is to hold the machine like a pistol that youre about to fire. While holding the machine at this angle move your head a little to one side to see if the machine is level.

Make sure that when tuning the tattoo machine the armature bar is held down to set the gapping between the contact screw and the front spring on the tattoo machines front spring. Work without wearing latex gloves. Several types of tattoo components require various strategies and creating of the machine in a specific approach and focusing.

Yes You can start lining with a shader machine. To tune a tattoo gun for lining select the right needle. For fine lines you want to set the gap between the front spring and the contact screw to about dime width.

Run the machine at 10V a little high for normal usage but a good jolt for troubleshooting. If they move while you are creating the lining then the entire design can be ruined. Six volts is appropriate for lining.

For a liner you need speed and opposed to a shader you need to lighten the armature bars. Tune Your Tattoo Machine in Three Steps Adjust the Power - Now its time to turn on the power and run your machine. In this video I guide you step by step through the process of tuning your coil machineStay up to date with all my latest upload by Subscribing clicking th.

Tune a rotary tattoo machine. How to Tune a Tattoo Machine. If you are new in the world of tattoos or maybe an aspiring tattoo artist this write-up is for you.

The sound shouldnt crackle or sound make a staccato noise such such as those made by machine guns or typewriters. Begin by pulling apart your machine starting with removing the tubes and needle from your tattoo arm. The setup of a tattoo machine varies depending on what type of line you would like to draw.

So you have a heavier spring in the front for a faster opening and closing and a shorter spring in the rear so that it hits harder on the skin. Adjust the voltage to get the speed youll need for your design and make sure the current is running smoothly. Maintain a proper gap between the armature bar and contact screw.

Doing this will always give you the gap you need to set your tattoo machine. You can adjust the duty cycle to 50 by monitoring it on the meter. Most tattoo artists adjust voltage by listening carefully to the sound of the gun--it should produce a steady buzz or a hum.

Video about Tune a Tattoo MachineSubscibe Like and comment video. Hold the machine so that you can see the contact screw tip closer to you. So they need very sharp needles to make crisp lines.

To set your machine for more nuanced detailed line work usually require a dime-sized gap. But it will be much easier for you to line if you have a liner tattoo needle that is long and thin instead of the fat needles that get used for shading. Remove the clip cord so as to be sure of it.

When tuning the tattoo machine hold an armature bar down to set a gap between the front spring and the contact screw. How to Tune a Liner Tattoo Machine Step 1. Nickel width is appropriate for doing shading.

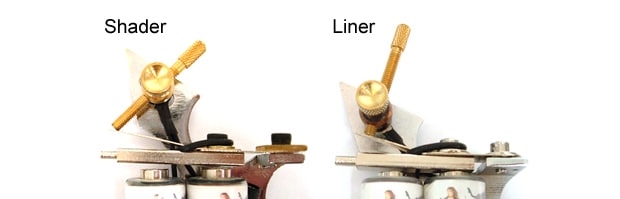

Shader nickel liner dime. Before proceeding make sure that everything is disconnected from the primary power source on your computer.

How To Tune Or Set Up Of A Tattoo Machine For Lining Or Shading Youtube

Machine Tuning Tattooing Basics Tattoo Magic

How To Tune A Tattoo Machine Liner And Shader Youtube

How To Tune Coil Tattoo Machine Cnc Tattoo Supply

Setting Up A Shader Tattoo Machine Gun

How To Tune A Tattoo Machine To Work

Step Five Adjusting The Armature Tattoo Machines Tattoo Magic

0 comments

Post a Comment